GF Machining Solutions is one of the world’s leading providers of complete solutions for tool and mould making and for the manufacture of precision parts. The portfolio includes milling, wire-cutting and die-sinking EDM machines, spindle systems, laser texturing, additive manufacturing and solutions in the areas of tooling, automation and digitalisation as well as customer services.

Visualising workpieces

Over the course of digitalisation, GF Machining Solutions wants to offer its customers further innovative and custom solutions in addition to existing IoT solutions for remote monitoring and remote support. The Digital Hub customer portal was developed with this in mind, which customers can use to select IoT solutions and install them on their own machines in a plug-and-play manner.

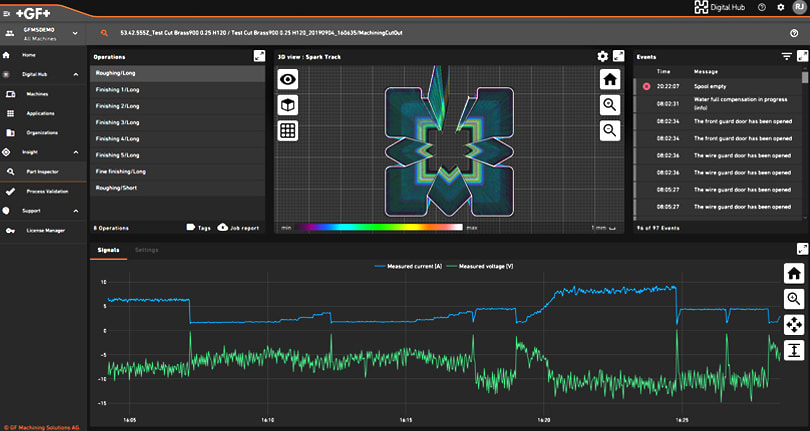

The Process Inspector was the first IoT application bbv developed on the Digital Hub. It visualises the manufacturing process for workpieces on the wire EDM machines.

Fewer errors – higher quality

In particular when operating complex machines and for the high-precision and demanding machining process, the solution helps with fault analysis and thus enables a higher level of quality. For example, when visualising workpieces in 2D or 3D, signal data is highlighted in colour, which considerably simplifies the work of the operator or machine operator.

“When it comes to developing new business models, bbv is a strong partner with a close connection to the industrial environment and tried-and-tested IoT experience.”

Jonas Ruesch, Head of Software Engineering Digital Business GF Machining Solutions

The IoT solution allows enormous volumes of data to be bundled and visualised. Depending on the machine type, several dozen signal values are sampled at 100 ms intervals. This means that several million measured values are saved each hour for a job. This is where the Spark Track technology from GF Machining Solutions comes into play – a technological revolution that allows the discharge point in wire EDM to be identified reliably.

Project insights

- Everything under one roof: bbv developed the entire Process Inspector together with the GF Machining Solutions development team – from the edge modules to the cloud backend to the web frontend and integration into the Digital Hub.

- In-depth insights into the manufacturing process: Several million measured values are stored and visualised each hour. This helps the operator analyse faults and enables a high level of quality.

- Comprehensive expertise: The bbv experts not only took on the technical lead for implementing the Process Inspector, but also advised those responsible on the architecture, cloud strategy and security.

- Agile approach: In addition to development, the bbv experts provided support for deploying new technologies and with agile product development.

- Efficient development: The collaboration in the distributed team at the two locations in Biel and Geneva was extremely efficient. In addition, development was accelerated by involving an external partner with expertise in the area of 3D visualisation in the web. The solution was developed to beta product maturity in about one year.

Our services in the project

The PDF version of the GF Machining Solutions Success Story can be found here.